The Brief

Develop a signature stem glass for Campari Spritz that is able to:

Identify Campari Spritz as the mature and competent choice (vs. Aperol Spritz and other competitors).

Be unique, distinctive, recognisable as the original Campari Spritz glass.

Express Campari’s brand character and premium essence.

Technically correct for the perfect serve, capacity and performance.

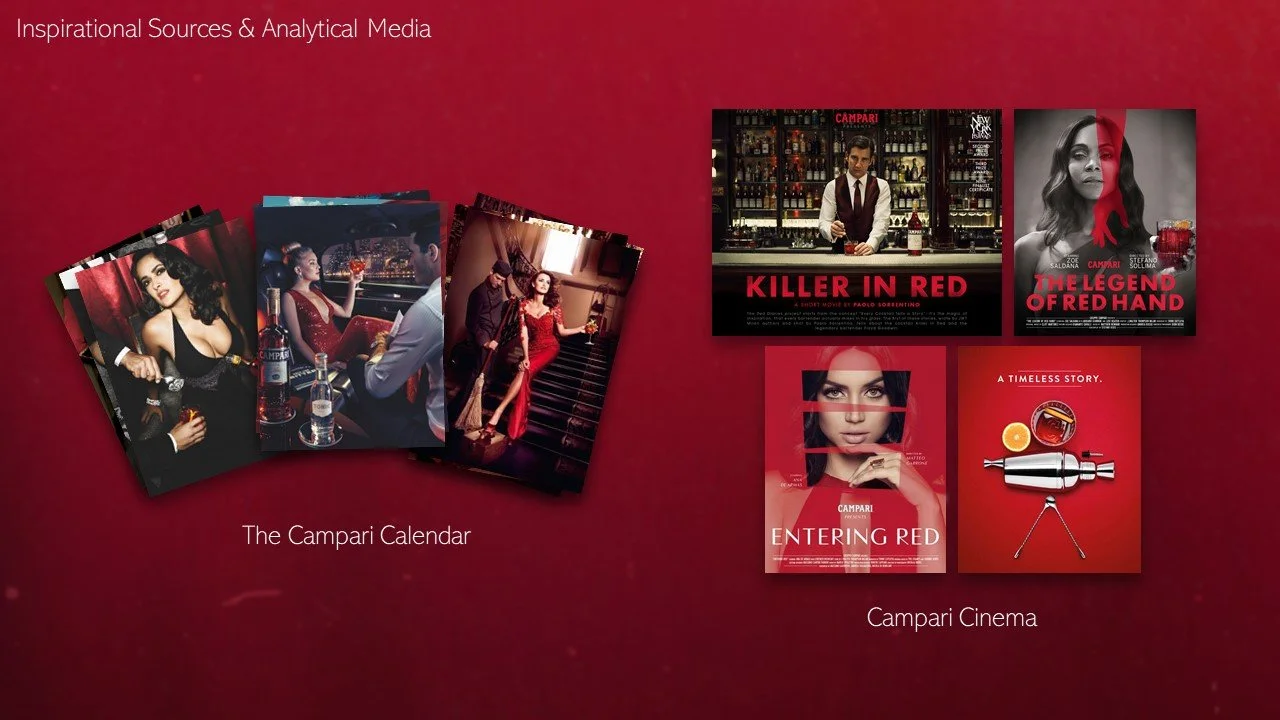

Driven by a deep dive into the history of Campari’s artistic contribution to photography & cinema, the research and analysis formed the over-arching creative direction for the project.

Often working with many famous and talented actors, models, photographers and directors, Campari are proud of their contribution to the world of photography and cinema.

This formed the basis for the research and analysis I conducted in order to devise an over-arching creative direction for the project.

Four key themes were identified; passion, elegance, confidence and composure, and were combined with dialogue from Entering Red (2019), “find the hands that create the perfect balance”, to form the thematic tone for the project.

During early stages of development, research was conducted into how a Campari Spritz is made. The glass must aid bar tenders and facilitate speed of service. This research and analysis helps inform design decisions during development, for example, the diameter of the lip of the glass must be wide enough to fit ice cubes, garnish and a stirrer.

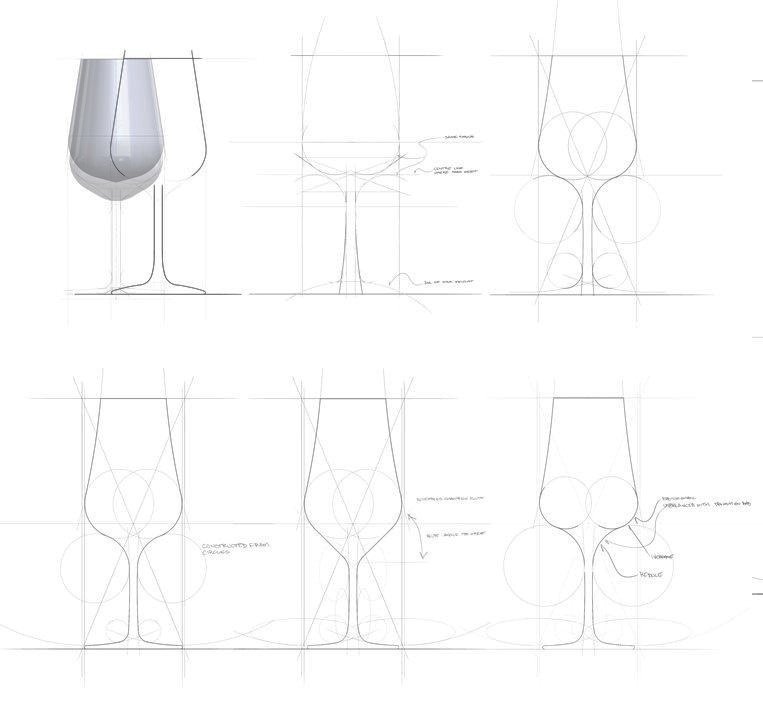

A quick sketching exercise to identify how the new design can differ from the previous.

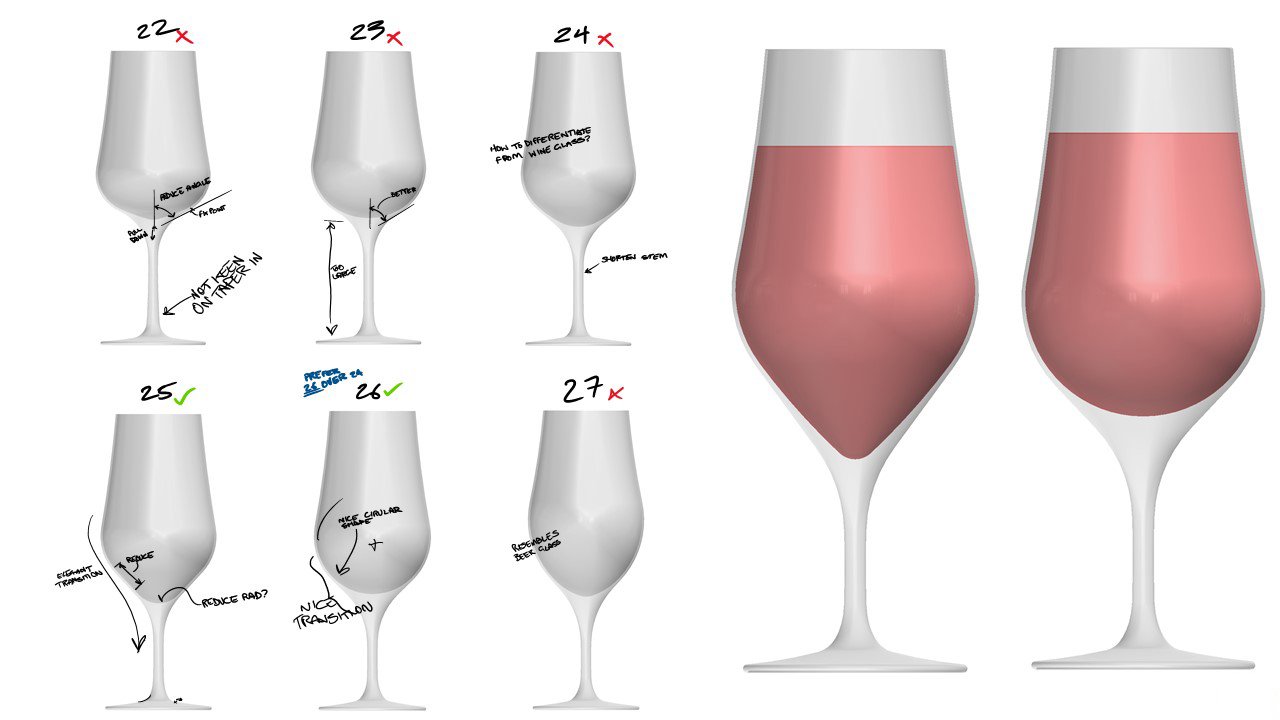

Multiple iterations were created to find the right balance between the bowl, stem and foot of the glass, with careful consideration of how each part of the glass transitioned into the next. After selecting a shortlist of sketches, concept development progressed into 3D CAD.

Using the sketches as a reference for the profile of the glass, the design was further refined during 3D development.

Aided by render software, I was able to simulate the way light would refract through the glass and its contents. The last few amendments were made based on the rendered visuals before committing to the final concepts.

This approach is hugely beneficial when reaching out to glass factories as it can save on time, cost and resources. We did not have to commit to producing expensive prototypes before settling on a realistic design. We can use realistic render visuals to communicate the design vision with the factories, and make quick iterations based on their feedback regarding feasibility and manufacturing constraints.